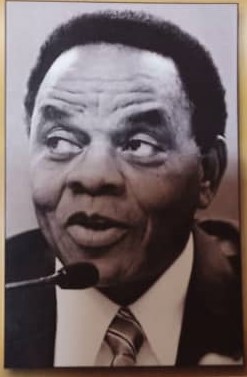

Prof. ADESINA, Adesoji, NNOM

engineering/technology

| Name : | Prof. ADESINA, Adesoji, NNOM |

|---|---|

| Award Year : | 2017 |

| Conferred by : | President Muhammadu Buhari, GCFR |

Professor Adesoji A. Adesina Born on April 2nd 1959 to the late Chief Adolphus Adediran Adesina and Chief (Mrs.) Bernice Adetoun Adesina, both of Ijebu-Igbo, Ogun State, Prof. Adesoji Adesina began his formal elementary education at St. Matthew’s School I, Ojowo, Ijebu-Igbo in 1965 and finished at St. Stephen’s School, Inalende, Ibadan in 1970. He then attended Lagelu Grammar School, Ibadan where he obtained the West African School Certificate with a Grade 1 Distinction in 1975. He immediately proceeded to the University of Lagos where he was among the first set of students in the new 5-year Chemical Engineering degree program. He graduated with a 1st class honours in June 1980. After a stint with Shell (as a well-site petroleum engineer), he joined the University of Port-Harcourt as Assistant Lecturer in 1981. By September 1982, he left for graduate work at the University of Waterloo, Canada where he completed his PhD in 1986 with a Canadian Commonwealth Scholarship award. He returned to the University of Port-Harcourt as Lecturer I in the same year. His passion for research eventually led to a Natural Sciences & Engineering Research Council of Canada-funded Research Associateship position at the University of Waterloo in 1989.

In 1991, he joined the University of New South Wales, Sydney, Australia as a lecturer and rose to full professorship in 2004. At UNSW, Prof. Adesina initiated and developed an internationally renowned group in Reactor Engineering & Technology. A distinguishing characteristic of his research accomplishments is the ability to mesh different levels of granularity (from molecular scale manipulation in catalyst synthesis through to reactor operation and analysis using advanced computational tools) to secure optimal process design and implementation from conceptual roots. This holistic approach and skills concentration is rarely found in a single research group and has been instrumental to the successful operation of innovative process technologies, including; (i) photocatalytic process for wastewater remediation and, (ii) the continuous flow extractive reactor for biodiesel production from non-edible oils. His research activities may be subsumed into three categories, namely;

Energy Activities in this category cover both fossil fuels and renewable energy sectors. Beginning with a doctoral work on the Fischer-Tropsch production of hydrocarbons from synthesis gas, Prof. Adesina's research has elucidated effect of dynamic fixed-bed reactor operation on product (gasoline range hydrocarbons) selectivity. His work has also shown that cobalt catalyst deactivation may be significantly reduced during the gas-to-liquid (GTL) conversion through periodic feed composition forcing with resonance benefits at practical operating frequencies (0.1-20 mHz). Enhanced olefin selectivity, catalyst longevity and hydrocarbon production rates (above that attainable in the steady-state space) were shown to be due to judicious perturbation of a large carbon pool normally latent under conventional operation. He also pioneered the application of electrical capacitance tomography for the diagnosis and control of high pressure slurry Fischer-Tropsch reactor rig. An important dimension of this development is the provision, for the first time, of an explicit mathematical relationship between fluid phase characteristics and reaction metrics. Furthermore, he has made extensive contributions to the literature on new catalytic technologies for natural gas reforming. He developed a novel thermally self-sustaining fluidised bed reactor for light alkanes reforming. This inventive strategy permits a higher hydrocarbon-to-steam (or carbon dioxide) ratio in the process feed and hence, superior carbon economy than current industrial practice allows while simultaneously achieving reduction in overall energy consumption and greenhouse gas emissions. The synthesis, characterisation and deployment of high performance molybdenum carbides/nitrides for both natural gas reforming and the Fischer-Tropsch reaction in his group has opened up new vistas for robust process intensification in multifunctional reactor technology for direct natural gas conversion to high value-added higher hydrocarbons. In the renewable energy area, Prof. Adesina has focused on the exploitation of biotransformation chemistry to optimise efficient reactor design for biofuels production from agrowastes. This is demonstrated in the patented extractive reactor technology for the continuous flow production of biodiesel from spent cooking oil. Among other advantages, this new process uses dilute ethanol solution (15%) rather than expensive 95% rectificate employed in current practice while concurrently removing glycerol by-product from the reacting phase to produce high purity (>99%) biodiesel. As a result of the novel integration of the reaction and separation steps into a single unit, the overall plant economics for the new technology is about 50% cheaper (footprint and capital costs) than existing industrial biodiesel manufacturing process. His research in renewable energy also bleeds into the health sector through development of new routes for the valorization of the glycerol (by-product of biodiesel production) to important pharmaceutical intermediates. Moreover, he has conducted collaborative studies on the enzymatic process for the production of biopharmaceuticals (for example, fermentation of benzaldehyde to L-phenyl acetyl carbinol for pseudoephedrine manufacture).

Environmental and Wastewater Treatment Technologies Prof. Adesina’s contributions to the development of advanced wastewater treatment technologies include, several seminal papers on photocatalytic kinetics of aqueous decontamination of principal pollutants, molecular synthesis of visible light-harvesting photocatalysts, the design and operation of an 18-litre pilot-scale photocatalytic bubble column reactor for continuous wastewater treatment that can process up to 1500 litres per day of toxic aqueous effluent to recyclable grade water. The photocatalytic technology has found application in the mining and petrochemical industries as well as in the rejuvenation of leachate from municipal solid waste landfills. In a companion technology based on solar illumination, an externally-irradiated rectangular tank containing inclined photocatalyst-coated plates, both biological and chemical detoxification were achieved and this is especially suitable as modular unit for wastewater regeneration in tropical environment. He has also carried out proprietary work for the defence industry in the reconditioning of aqueous discharge from the propellants and explosives production facility. Furthermore, his research yielded improved efficiency for the manufacture of energetic products using analytical engagement of computational fluid dynamics modelling of the mixing process.

Process intensification and interdisciplinary work Process intensification is a strategic engineering integration (of material, energy and property) paradigm with the objective of minimizing utilities and feedstock for a specified throughput. In view of its wider ramifications and the inevitable nonlinearities associated with process integration and hybridization, Prof. Adesina’s work in this area has involved the implementation of mathematical programming techniques such as artificial neural network, computational fluid dynamics as well as statistical modelling and optimisation, of both unit and plant intensification. This is typically followed with empirical verification that substantiates the process mathematics. In this endeavour, he has collaborated with chemists, biotechnologists and electrical engineers. He won (jointly with computer engineering colleagues) an Australian research award for the innovative development of a nano-sensor network communication system for molecular level control of catalyst selectivity for the GTL process. In a spate of recent papers with Chinese colleagues, he has introduced novel adsorption techniques for the recovery of uranium and thorium from nuclear wastes using marine resources while simultaneously alleviating environmental concerns.

Overview To date, Prof. Adesina is credited with nearly 450 refereed publications, patents and books. He has supervised more than 100 graduate students to completion, including 42 PhD alumni and 27 postdoctoral research associates, with a truly global hue. Among these former students are university professors in highly-ranked institutions, executives of the petrochemical processing industries, government dignitaries and captains of engineering design & consulting firms located throughout China, South-East Asia, Middle East, Europe, USA, Canada & Australia. He has won over $15 million in competitive research grants from government and industry sponsors.

He is a Member of the Nigerian Society of Chemical Engineers and the American Institution of Chemical Engineering as well as a Fellow of both the Institution of Chemical Engineers (UK) and Royal Australian Chemical Institute. He also served for many years on the Council of the International Association of Catalysis Societies, the Asia-Pacific Forum for Chemical Reaction Engineering and the World Congress on Industrial Process Tomography. He was the only African person on these international bodies. He is also on the editorial/advisory boards of major journals in chemical engineering and catalysis including Catalysis Communications. He is an external assessor to several highly reputable universities across the globe for doctoral examination, professional accreditation and promotion matters.

Prof. Adesina’s contributions to the international engineering community over the past three decades are particularly relevant to human development efforts. Specifically, they highlight the necessity to efficiently harness Nigeria’s resources for favourable market competition in the 21st century knowledge economy in a bid to facilitate societal transformation. More recently, he has turned attention to the theological underpinnings of human nature and destiny having obtained a Master of Divinity from the prestigious evangelical institution, Fuller Theological Seminary, California, USA.

It is therefore my utmost pleasure to present to you, Mr. President and Commander-in-Chief of the Nigerian Armed Forces, this distinguished Nigerian, Prof. Adesoji Adesina, as the recipient of the 2017 NNMA Award for Engineering & Technology

Prof. CHIDUME., Ejike Charles, LATE,, NNOM

Science

Prof OLUTOYE, Olurotimi Oluyinka, NNOM

Medicine

Prof EKHAGUERE, O. Samuel Godwin, NNOM

Science

Prof. OLUFEMI, OBAFEMI, NNOM

Humanities, arts and culture

Mr ONOBRAKPEYA, Paul Bruce, NNOM

Humanities, arts and culture

Prof. ADESINA, Adesoji, NNOM

Engineering/technology

Professor SADIK, Omowunmi, NNOM

Science

Professor OJAIDE, Tanure, NNOM

Humanities